MOMA Titanium Minerals Mine (WCP)

Moma Titanium Minerals Mine

New Wet Concentrator Floating PlantLocation: North-Eastern Mozambique | Client: Aveng Engineering

Project Description

Kenmare Resources plc appointed Aveng Engineering to detail design, construct and commission the expansion of the Moma Titanium Minerals Mine on the north-eastern coast of Mozambique. The Moma Mine contains deposits of heavy minerals, which include the titanium minerals ilmenite and rutile, as well as the zirconium silicate mineral, zircon. Aveng Engineering appointed Greene Consulting Engineers (Pty) Ltd for the design of the floating plant superstructure, as well as the bulk earthworks associated with the dry dock (construction stage) of the floating plant. Greene was also responsible for the construction monitoring of the project.

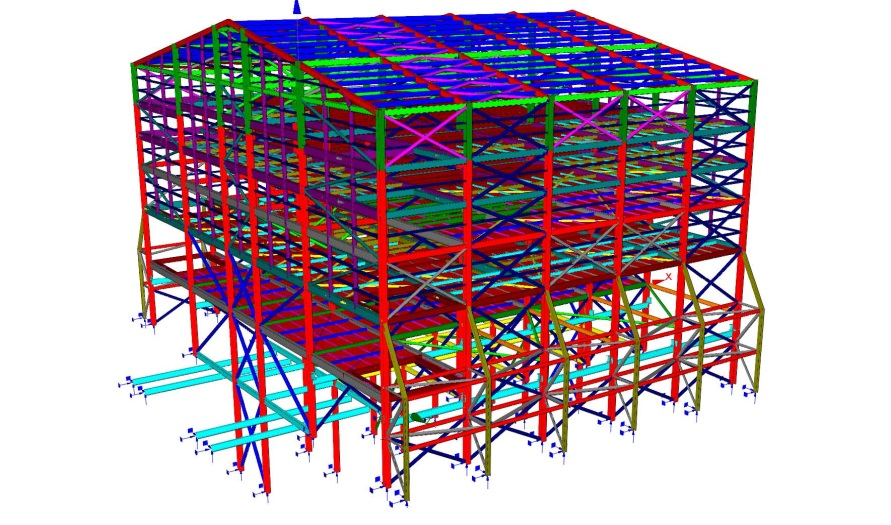

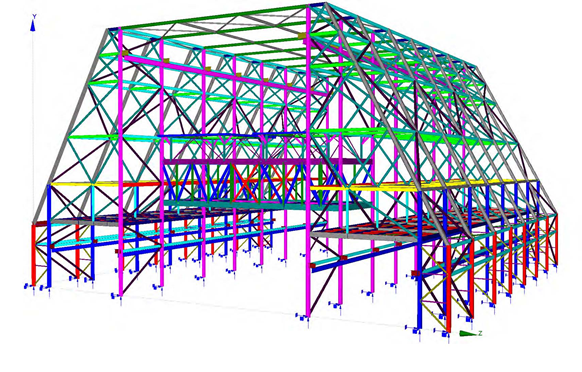

We designed the superstructure of the floating process plant, which is seven storeys high with a plan area as large as a rugby field. The total mass of the empty plant is approximately 5 500 tonnes and the maximum design mass of the plant was calculated as 10 500 tonnes.

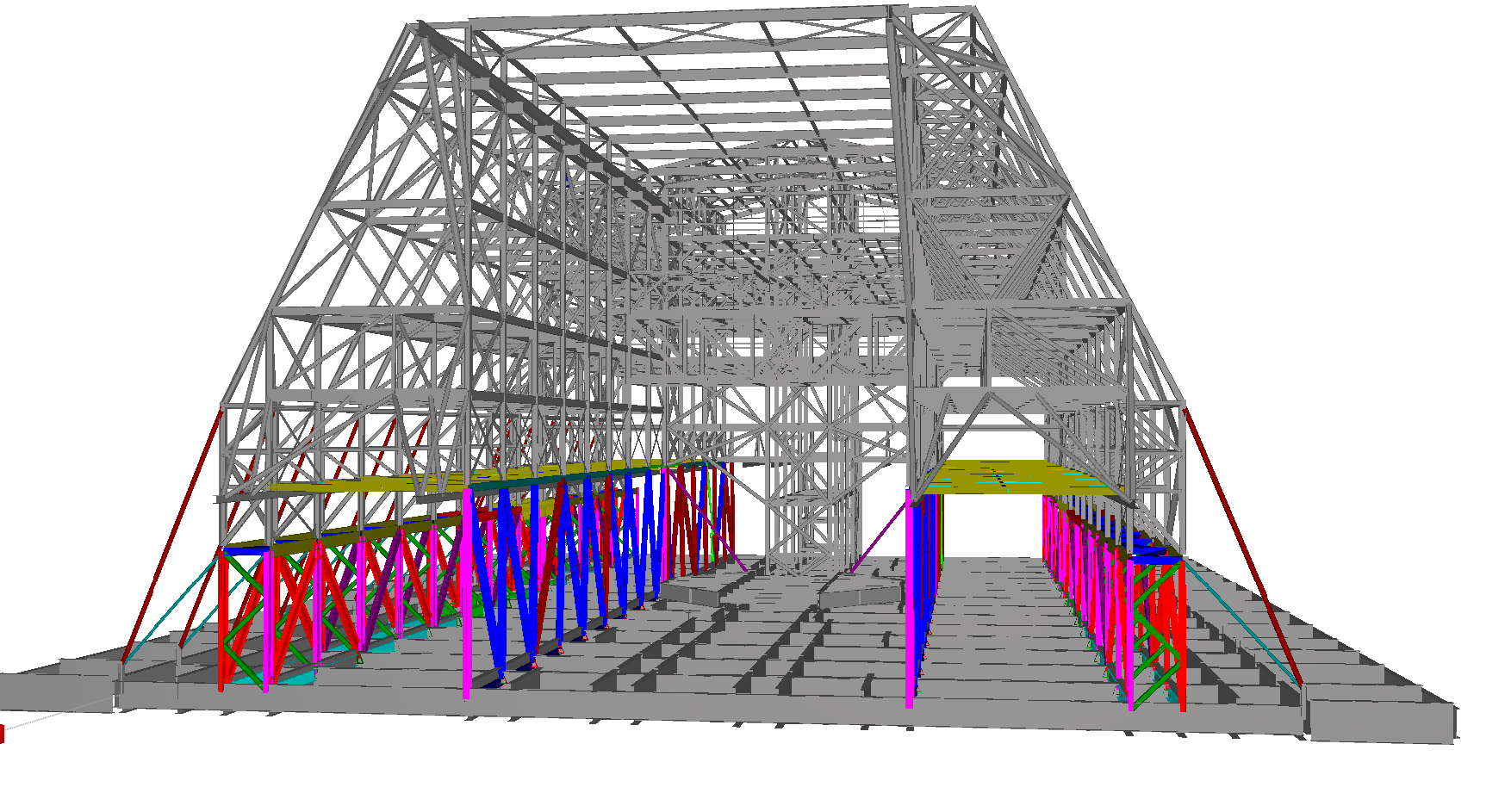

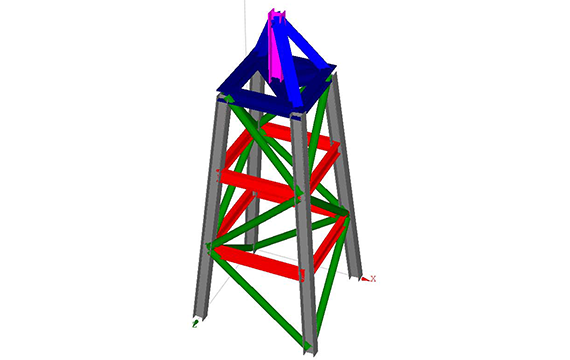

The steel superstructure consists of a spiral building, crane building, the vibrating-screen supporting structure, the mooring towers and pipe bridges. The plant was built on 15 steel pontoons (designed by Triton Naval Architects), connected by 8m high steel trusses called strong-backs. The pontoons and strong-backs ensure that the operating plant stays afloat in a large man-made pond.

BIM ‘Inventor’ model

Strongback trusses. These trusses are the backbone structure of the floating plant, providing stiffness to the plant. These trusses were used to transfer the loads from the superstructures down to the pontoons.

The vibrating-screen supporting structure is 11 m high, and is supported directly by the pontoons. The dynamic loads from two vibrating screens acting at this height had to be accounted for in the design. The natural frequencies and displacement amplitudes had to be evaluated to satisfy design criteria.

Construction Process

Total project value: US $ 380 million

Related Projects

Maboneng Precinct

Valarchi – New Food Factory

New 75MW Solar Farm

Impilo Entsha

Canelands Trust

Delta Plant

Xinavane Sugar Mill

Bokoni Platinum Mine

Isa Carstens Training Academy

MOMA Titanium Minerals Mine (MSP)

Factory Food Safety Assessments (Botany Bay, Australia)

Foundations for Surface Mine Ventilation Fans (Ghana)

Expanded Public Works Programme

Comments are closed.